Taking steps to improve safety by design

One particularly important piece of PPE is metatarsal safety boots, something that all our site-bases employees are required to wear.

Employees working in our Contracting business raised concerns about the performance and comfort of our existing safety footwear. Long hours on their feet, variable ground conditions and wet weather can all result in footwear becoming uncomfortable for the wearer. Concerns centred around the weight of the boot, discomfort caused by the steel toe cap and metatarsal protection, boots leaking in wet weather, overall quality and the need to replace them within a few months of purchase.

So, in order to address these concerns, Tarmac took a truly collaborative approach by partnering with our leading supplier, Mascot Workwear.

Engagement began with Mascot working closely with our teams in Contracting to fully understand the challenges that employees were facing with their boots. These discussions formed the basis of a complete boot redesign taking into account the needs of Tarmac’s employees. Rigorous factory testing ensured that the new design solved the common concerns such as comfort, water-proofing and durability.

A small group of employees were asked to test the new design by Mascot as part of initial trials followed by more wider trials at Tarmac sites including our contracting depot at Agecroft.

Successful trails and positive feedback from the workforce have meant that this next generation of safety footwear has gone into full production and is now readily available on the UK market.

An employee Agecroft commented: “It was great to be asked to be involved in the process of redesigning our safety boots. Not only did this show that Tarmac was listening to our concerns over our existing boots’ performance, but it also meant that the new product reflects the real challenges that we face working on site.

By working closely with our supply chain partner, Mascot, Tarmac was able to fully address employee concerns and provide a new, bespoke safety footwear solution whilst involving employees on the journey. In addition, Tarmac was able to ensure that the materials used for the new boot were sources and manufactured in a responsible and sustainable way.

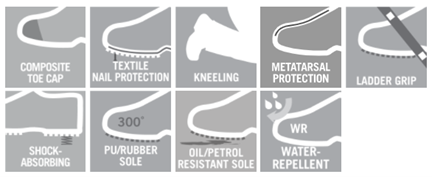

Key features of the new safety footwear include:

- Made from full grain leather which improves breathability, durability and helps to prolong the life of the boot

- Toe cap protection consists of a lightweight composite material, providing improved safety performance

- Composite toe cap and textile midsole do not conduct heat or cold; providing and extra level of comfort when working in either hot or cold environments

- Additional cushioning material to the inner heal helping to prevent rubbing and causing discomfort to the wearer during long shifts.

Download case study